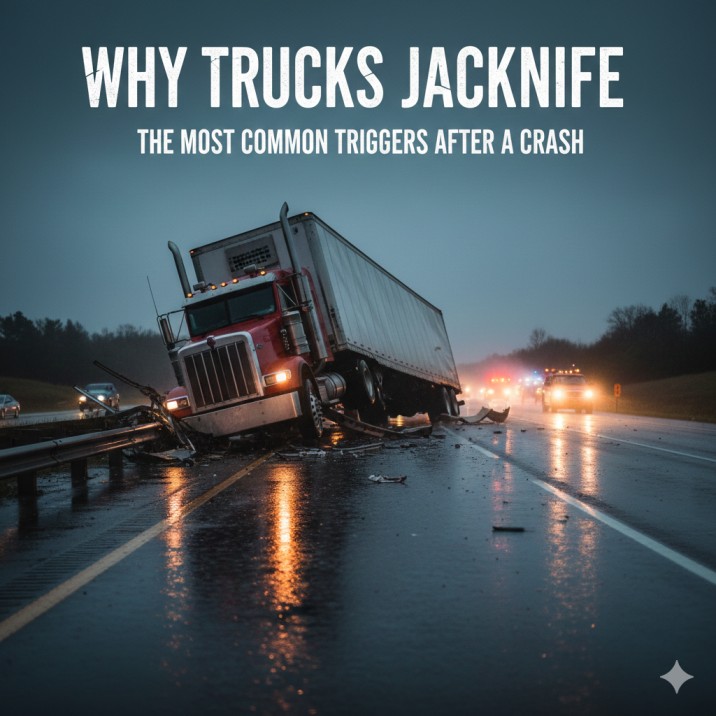

A jackknife crash is not just a truck accident; it’s a quick and violent event that can create a disaster across multiple lanes. When a trailer swings and the cab moves toward it, the truck can slide sideways, hitting cars with nowhere to go. This moment can feel surreal for drivers in smaller vehicles as headlights come from unexpected angles and tires screech.

Jackknife accidents often start with small issues like incorrect braking, slippery roads, or a shifting load. Understanding these triggers helps victims realize that the crash was not just bad luck but could have been avoided due to speed, fatigue, poor maintenance, or unsafe work pressure. If you were injured in a jackknife crash, Dulin McQuinn Young can help find out what caused the accident and whether negligence was involved.

What a Jackknife Really Is (and Why It’s So Hard to Stop Once It Starts)

A jackknife happens when the trailer and truck stop moving straight and form a sharp angle, like a folding pocketknife. This occurs when there’s a loss of balance between traction and momentum. The trailer continues moving forward while the truck slows down or loses grip, causing the trailer to take the lead.

Once the swing starts, the driver has only a moment to react. If the tires are sliding, steering becomes unreliable. Braking harder can make the swing worse. Stopping the sideways force of a fully loaded trailer, which can weigh tens of thousands of pounds, is very difficult—it’s like trying to stop a rolling building.

Hard Braking When the Trailer Still Has Momentum

Hard braking is one of the most common jackknife starters. When a driver brakes suddenly, the tractor can slow faster than the trailer. If the trailer’s wheels lose traction or lock up, the trailer begins to drift sideways while still pushing forward. That forward shove is what forces the hinge point—the connection between tractor and trailer—to fold.

This often happens in real-world situations that look “normal” at first: traffic slows unexpectedly, a car cuts in front, or a light changes. Passenger vehicles may stop quickly, but a semi needs distance. When that distance doesn’t exist, hard braking becomes unavoidable—and jackknife risk spikes.

Rain, Ice, and “Invisible Slip” Conditions

Bad weather can make roads slippery and catch drivers off guard. A truck may seem steady but can suddenly hit a smooth spot where it loses traction. On slippery roads, even a small tap on the brakes can cause a skid.

Skids can quickly worsen. Once the trailer starts sliding, it can throw the whole truck off balance. Its large flat surface can catch wind and water, making it less stable. Weather doesn’t cause bad driving, but it reveals problems when drivers don’t adjust their speed and distance.

Speed That’s “Legal” but Still Reckless for the Moment

Many jackknife wrecks happen below the posted speed limit. That surprises people until they realize truck safety depends on conditions, not numbers on a sign. A curve, downhill grade, wet road, heavy load, or tight merge zone can make “legal speed” dangerous.

Speed becomes especially risky when combined with a last-second reaction. The faster a truck is moving, the more force is needed to slow it down. More force means more strain on traction. And when traction breaks, the trailer doesn’t “slow down neatly”—it swings. In many jackknife cases, speed isn’t the only factor, but it’s the accelerant that turns a mistake into a catastrophe.

Braking While Turning (Curves, Ramps, and Exit Lanes)

A tractor-trailer faces danger when turning and braking at the same time, especially on exit ramps or curves. Turning shifts the trailer’s weight, and braking adds forward force, creating instability that can cause the trailer to drift outward.

Jackknife accidents often occur near interchanges, highway ramps, and mountain grades. Drivers may enter a curve too quickly and brake while turning, leading to a loss of balance and the trailer breaking loose.

Load Shift and Cargo That Fights the Driver

Cargo can be silent…until it moves. When freight isn’t secured properly or weight is unbalanced, the trailer can behave unpredictably. A small internal shift can change handling, make the rig sway, and reduce traction on specific axles. Then, when the driver brakes, the load’s movement can push the trailer off line.

Some loads are naturally more unstable. Partially filled tanker trailers are known for liquid surge, where the fluid slams forward under braking and sways side-to-side during steering. That motion can amplify a skid and make jackknife recovery harder, even for an experienced driver.

Brake and Tire Issues That Create Uneven Stopping Power

Jackknifes aren’t always “driver error.” Sometimes the rig’s equipment is part of the problem. If brakes are worn, improperly adjusted, or uneven across axles, the truck may stop inconsistently—causing the trailer to pull or swing. When the braking force isn’t balanced, the rig can twist itself into a jackknife.

Tires matter just as much. Bald tread, underinflation, mismatched tire wear, or cheap replacement tires reduce grip. A truck doesn’t need to be “missing tires” to be unsafe. It just needs one weak point where traction gives out before the rest of the vehicle is ready.

Following Too Closely and Getting Forced Into “Panic Brakes”

Tailgating is deadly with trucks because it steals time. A passenger car may brake and stop in a short distance. A loaded semi cannot. When trucks follow too closely, every slowdown becomes an emergency—meaning the driver’s only option is to slam the brakes.

Jackknifes in traffic often begin with something minor: a driver glances down, looks up too late, and brakes hard. Once that happens, the trailer can start swinging even if the driver “meant well.” In these cases, the root cause isn’t the braking—it’s the lack of space that made hard braking inevitable.

Fatigue and Slow Reactions That Turn Problems Into Crashes

Fatigue doesn’t always look like falling asleep. It often looks like delayed decision-making. A tired driver brakes later, misreads road conditions, responds too aggressively, or overcorrects once the trailer starts slipping. Instead of a controlled slowdown, you get a panic reaction in a vehicle that cannot afford one.

Fatigue is also linked to risk-taking. Drivers under schedule pressure may keep speed higher than safe during rain, push through traffic instead of backing off, or skip rest because they feel they “have to.” That’s how a driver ends up in a situation where jackknifing becomes far more likely.

Why the Jackknife Happened

Jackknife crashes often leave clues that explain whether the trailer swing was unavoidable—or the result of preventable decisions. Preserving evidence early is key.

- Roadway evidence tells the first part of the story. Skid marks and yaw marks may show when the trailer began to swing and whether it happened before impact.

- Vehicle damage patterns matter. Impact angles and crush points can reveal if the trailer swept across lanes or folded sharply during braking.

- Conditions and visibility provide context. Weather, road surface, construction zones, signage, and sightlines can indicate whether the driver had enough time and distance to react safely.

- Trucking records often reveal deeper causes. Driver logs, GPS data, dispatch messages, and maintenance records can help determine if a crash was due to “unexpected conditions” or predictable risks like speed, fatigue, poor maintenance, or unsafe loading.

Why Responsibility Often Goes Beyond the Driver

A jackknife accident can stem from a driver’s mistake, but often bigger issues contribute. Companies create unsafe conditions by rushing deliveries, overloading schedules, ignoring maintenance alerts, or not enforcing safe driving rules in bad weather. Loaders can also contribute by not properly securing cargo. Maintenance workers can play a role when they fail to service brakes and tires correctly.

Jackknife accidents usually result from a series of preventable mistakes. When that leads to serious injuries, it’s important to question who created the risks beforehand.