In an increasingly competitive global electronics market, two strategic decisions profoundly influence product success: how effectively you optimize manufacturing costs while maintaining quality, and which electronics manufacturing services partner you choose to execute your production. These interconnected decisions affect not just unit costs and profit margins but also time-to-market, product reliability, supply chain resilience, and, ultimately, competitive position. For CEOs, CTOs, procurement managers, and operations leaders, mastering both cost-optimization strategies and partner-selection criteria has never been more critical.

The traditional approach to electronics cost optimisation focused primarily on negotiating lower component prices or moving production to the lowest-cost geography. While these factors remain relevant, contemporary best practices recognize that effective cost optimization requires a holistic approach that examines the entire product lifecycle—from initial design decisions through component selection, manufacturing processes, quality control, logistics, and long-term reliability. Studies consistently show that design decisions made early in development lock in 60-80% of eventual manufacturing costs, making upstream optimization far more impactful than downstream cost-cutting.

Simultaneously, the choice of manufacturing partner has evolved from a tactical procurement decision to a strategic business consideration. The disruptions of recent years—component shortages, logistics challenges, geopolitical tensions—have demonstrated that the lowest-cost provider may not deliver the lowest total cost of ownership when supply chain disruptions cause production delays, quality issues generate warranty costs, or communication challenges slow product development cycles. Leading companies now evaluate potential EMS partners using a multidimensional framework that considers technical capabilities, quality systems, supply chain management, financial stability, cultural fit, strategic alignment, and pricing.

This comprehensive guide explores both critical dimensions: first, it examines proven strategies for electronics assembly (PCBA) cost optimization, then provides a detailed framework for selecting manufacturing partners who can execute cost-effectively while delivering quality, reliability, and strategic value. Whether you’re developing your first product or optimizing an established portfolio, the insights presented here will enable more informed decisions that enhance both profitability and competitive position.

Understanding Total Cost of Ownership in Electronics Manufacturing

Before diving into specific optimization strategies, it’s essential to establish a comprehensive framework for evaluating manufacturing costs. The unit cost—the price paid per assembled board or finished product—represents just one component of the total cost of ownership. A complete analysis must consider development costs including NPI support and design optimization, material costs for components and PCBs, manufacturing costs for assembly and testing, quality costs including inspection, rework, and warranty claims, logistics costs for freight and duties, inventory carrying costs tying up working capital, and opportunity costs from delayed market entry or reduced sales due to quality issues.

This total-cost perspective often reveals that decisions that minimize unit cost actually increase total cost. For example, selecting the absolute lowest-cost components might reduce BOM cost by 5%. Still, if those components have longer lead times that require larger inventory buffers or higher failure rates that generate warranty costs, the total cost actually increases. Similarly, choosing a manufacturer solely based on the lowest price quote might backfire if quality issues cause production delays, require expensive rework, or lead to field failures that damage the brand reputation.

Leading companies employ cross-functional teams evaluating cost decisions from multiple perspectives. Engineering evaluates technical suitability and reliability implications. Procurement assesses component availability and supply chain risks. Manufacturing evaluates assembly complexity and its impact on yield. Quality examines failure mode implications. Finance calculates the total cost across the product lifecycle. This comprehensive evaluation reveals the truly optimal decisions rather than locally optimal choices that increase total cost.

Bill of Materials Optimization: The Foundation of Cost Management

The Bill of Materials—the complete list of components that make up a product—represents the single most excellent leverage point for cost optimization. BOM costs typically account for 60-80% of total manufacturing costs, and decisions made during BOM development have cascading effects throughout the product lifecycle. Effective BOM optimization requires a systematic approach implemented early in development, when flexibility is highest, and changes are least expensive.

Component Selection and Standardization

Component selection profoundly influences both direct costs and manufacturing efficiency. Each unique component in a BOM creates complexity—it must be sourced, qualified, stocked, programmed into assembly equipment, and inspected. Reducing component variety through strategic standardization delivers multiple benefits: reduced purchasing complexity and potentially better pricing through volume consolidation, simplified inventory management with fewer unique parts to stock, faster assembly setup with fewer component changeovers, reduced quality risk from fewer potential part number errors, and enhanced supply chain resilience with more standard, readily available components.

Standardization strategies include establishing preferred part libraries containing pre-qualified, readily available components that designers should use as first choice, defining component families where similar functions use the same component family across multiple products, implementing design rules requiring engineering justification for introducing new unique components, and conducting regular BOM reviews identifying opportunities to consolidate component variety across product lines.

The application of standardization requires balancing consistency with optimization for specific applications. Unthinkingly using the same components everywhere can miss opportunities to use a more optimized part that would significantly improve performance or reduce costs in a particular application. The goal is thoughtful standardization that captures most benefits while retaining flexibility for cases where unique requirements justify exceptions.

Design for Manufacturability and Assembly

Manufacturing costs and quality profoundly influence design decisions made before the prototype. Design for Manufacturability and Design for Assembly principles applied during development reduce assembly complexity, improve yields, and lower costs. Key DFM/DFA principles include minimizing PCB layer count while meeting electrical requirements, selecting standard component packages readily available and easily assembled, providing adequate spacing between components enabling automated assembly, avoiding unnecessarily tight tolerances that increase manufacturing difficulty and cost, designing PCBs with standard dimensions compatible with assembly equipment, and incorporating test points enabling efficient testing.

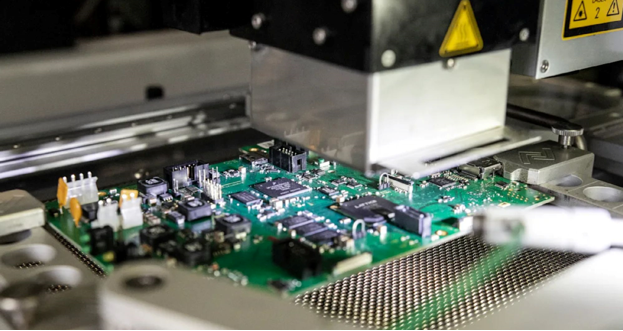

Engaging manufacturing partners early in development ensures that design decisions take manufacturability into account. Experienced EMS providers can review preliminary designs, identifying potential manufacturing challenges while changes remain inexpensive. They recommend component spacing adjustments to enable faster pick-and-place operation, suggest alternative package types that are more reliable in reflow soldering, identify tolerance specifications that are tighter than necessary for function but add cost, or propose PCB layout modifications to improve test coverage. This collaborative approach prevents costly design re-spins and optimizes designs for efficient manufacturing.

Many companies implement formal design review checkpoints where manufacturing engineers evaluate designs before committing to tooling or volume production. These reviews catch issues early, when corrections are straightforward, rather than discovering problems during production, when changes are expensive and delay market introduction.

Lifecycle Management and Obsolescence Planning

Electronic components have finite lifecycles. Manufacturers discontinue products as technology advances or demand declines. Products designed around components nearingthe end of life face supply disruptions and forced redesigns. Proactive lifecycle management prevents these costly situations through systematic monitoring of component lifecycle status, planning for longevity by preferring components early in their lifecycle over those nearing obsolescence, establishing alternate sources identifying multiple suppliers or alternate components during design, implementing end-of-life management with processes for handling component obsolescence notifications, and considering total cost including availability and lifecycle when evaluating component choices.

Sophisticated BOM management tools now incorporate component lifecycle data and automatically flag components approaching obsolescence or exhibiting supply constraints. This early warning enables proactive decisions—perhaps qualifying an alternate component before the primary becomes unavailable, or building a buffer inventory of a critical long-lead component facing allocation constraints. Reactive responses to obsolescence—scrambling to find alternatives or paying premium prices for dwindling inventory—cost far more than proactive lifecycle management.

Manufacturing Process Optimization: Efficiency and Quality

Beyond component costs, manufacturing process efficiency significantly impacts total costs. Processes that maximize first-pass yield, minimize manual operations, reduce cycle times, and ensure reliable quality deliver substantial cost advantages over less optimized approaches.

Optimizing Assembly Processes

Assembly efficiency depends on numerous factors, including board design compatibility with automated equipment, component packaging that enables efficient automated handling, optimized pick-and-place programming that minimizes placement time, and balanced production lines that prevent bottlenecks. Companies working closely with manufacturing partners during NPI can optimize these factors before committing to volume production.

For example, component placement optimization considers not just electrical connectivity but assembly efficiency. Grouping similar components reduces the number of nozzle changes on pick-and-place equipment. Orienting components consistently simplifies programming. Placing larger components before smaller ones prevents shadowing. These minor optimizations can reduce assembly time by 10-20%, thereby lowering manufacturing costs and improving throughput.

Panel utilization—fitting multiple smaller boards into standard panel sizes—provides another optimization lever. Efficient panel layouts minimize wasted board area while accounting for assembly constraints, such as the spacing required for tooling holes and fiducial marks. Optimized panelization might fit two additional boards per panel, reducing PCB cost per unit by 15-20%.

Quality as a Cost Reduction Strategy

High quality and low cost are not opposing goals; they are actually aligned. Poor quality incurs costs through assembly rework to correct defects, scrap from unrepairable defects, extended testing to catch issues that should have been prevented, warranty costs from field failures, and opportunity costs from delayed shipments and damaged customer relationships. World-class manufacturers achieve both low costs and high quality through process control, preventing defects rather than inspecting them.

Statistical process control monitors key process parameters detecting trends before they cause defects. Automated optical inspection catches assembly defects immediately when correction is least expensive. Comprehensive testing verifies correct operation before shipping. Root cause analysis prevents recurrence when issues do occur. These quality practices, rather than adding cost, dramatically reduce total cost by preventing expensive downstream problems.

Working with manufacturing partners who prioritize quality culture over minimal price generates better total cost outcomes. Look for evidence of quality commitment including comprehensive quality management systems certified to relevant standards, transparent quality metrics showing defect rates and trends, proactive problem solving with systematic root cause analysis, investment in quality equipment and training, and willingness to discuss quality performance openly including challenges and improvement initiatives.

Supply Chain Management: Optimizing Procurement and Logistics

Effective supply chain management represents another critical dimension of cost optimization. Component procurement, inventory management, and logistics collectively influence costs, lead times, and working capital requirements.

Strategic Sourcing and Supplier Management

Component costs vary significantly based on sourcing strategies. Effective approaches include consolidated purchasing that leverages volume across multiple products or customers; negotiated agreements that establish pricing and allocation with key suppliers; market intelligence to monitor pricing trends and identify optimization opportunities; alternative sourcing that qualifies multiple sources for critical components; and geographic optimization that balances component costs against logistics and lead times.

Manufacturing partners with sophisticated procurement operations add substantial value through established supplier relationships that provide allocation during shortages and favourable pricing, market intelligence on component trends and emerging issues, procurement systems that enable efficient purchasing and traceability, and supplier quality management that ensures consistent component quality.

Recent years’ component shortages have highlighted the value of effective supply chain management. Companies with sophisticated procurement strategies and strong supplier relationships maintained better component availability than those that treated procurement as a purely transactional, lowest-bid process.

Inventory Optimization

Inventory ties up working capital while enabling production continuity and buffering against supply disruptions. Optimal inventory balances these competing concerns through demand forecasting that drives purchasing decisions, safety stock calculations that balance working capital cost against shortage risk, inventory turnover monitoring to identify slow-moving inventory, and vendor-managed inventory programs for high-volume components, where suppliers manage stocking.

Just-in-time inventory strategies minimize working capital but require reliable supply chains and accurate demand forecasting. Buffer inventory protects against disruptions but increases costs and the risk of obsolescence. The optimal balance depends on product characteristics, demand predictability, component lead times, and supply chain reliability. Collaborative planning with manufacturing partners enables inventory optimization across the entire supply chain.

Selecting the Right EMS Partner: A Strategic Framework

While cost-optimization strategies are essential, their effectiveness depends heavily on the selection of manufacturing partners. The right partner brings not just competitive pricing but technical expertise, quality systems, supply chain management, and strategic alignment that enhance product success. A comprehensive partner evaluation framework considers multiple dimensions beyond price.

Technical Capabilities and Capacity

Manufacturing partners must have capabilities that match your product requirements. Evaluation criteria include assembly technologies with appropriate SMT, THT, and mixed-technology capabilities, equipment capability handling your component types including fine-pitch, BGA, and micro-components, production capacity matching your volume requirements with room for growth, testing capabilities providing appropriate test coverage, complementary services like box build, coating, or potting if required, and engineering support for DFM review, NPI, and ongoing optimization.

Site visits during partner evaluation provide invaluable insights. Observe equipment condition and maintenance, organization and cleanliness suggesting process discipline, material handling and traceability systems, quality control integration into production flow, and employee engagement and morale. Well-managed operations are typically evident within minutes of entering a facility.

Request references from customers with similar products or requirements. Discuss their experience with technical capabilities, problem-solving when issues arise, communication effectiveness, and overall satisfaction. Candid conversations with current customers reveal information not apparent in marketing materials.

Quality Systems and Performance

Quality performance directly impacts total cost through reduced rework, scrap, and field failures. Evaluate potential partners’ quality systems through certifications relevant to your industry including ISO 9001 for general quality management, AS9100 for aerospace, ISO 13485 for medical devices, and IATF 16949 for automotive. Also consider quality metrics, including defect rates expressed in parts per million, first-pass yield indicating process control, customer return rates showing field performance, and audit scores from customer assessments.

Quality culture reveals itself through transparent communication about quality performance, including challenges; proactive problem-solving with systematic root-cause analysis and corrective actions; continuous improvement initiatives; employee involvement; investment in quality equipment and training; and management commitment, evidenced by priorities and resource allocation.

Be cautious of partners who are unwilling to discuss quality performance transparently. Leading manufacturers take pride in quality achievements and openly discuss their systems and results. Evasiveness or vague assurances without supporting data suggest potential problems.

Supply Chain Management and Flexibility

Supply chain management capability influences delivery reliability, component availability, and cost optimization. Evaluate partners’ supply chain capabilities including established supplier relationships providing allocation and pricing advantages, procurement systems enabling efficient purchasing and traceability, component engineering for obsolescence management and alternative sourcing, inventory management balancing working capital against availability, and logistics management optimizing freight and delivery.

Recent supply chain disruptions highlighted the critical importance of supply chain expertise. Partners with sophisticated supply chain management navigated shortages better, maintaining production continuity, while others faced extended delays. During evaluation, discuss how potential partners managed recent challenges. Their responses reveal capability and resourcefulness.

Communication and Cultural Fit

Manufacturing partnerships succeed through effective collaboration requiring clear communication and compatible working styles. Evaluate communication effectiveness and cultural alignment through responsiveness to inquiries and thoroughness of responses, clarity and professionalism in documentation and proposals, designated account management providing single point of contact, language capabilities if working across borders, time zone alignment or willingness to accommodate scheduling differences, and overall impression of whether the partner listens, understands requirements, and demonstrates genuine interest in your success.

Geographic proximity facilitates communication and collaboration through compatible time zones, enabling real-time discussion; reasonable travel distance for site visits during development and issue resolution; shared or similar business culture and practices; and potentially aligned holidays and work schedules. This consideration has driven nearshoring trends, as proximity advantages often outweigh purely cost-driven offshore strategies.

Financial Stability and Strategic Alignment

Manufacturing partnerships often span years or decades. Partner financial stability and strategic alignment ensure sustainable relationships aligned with your long-term interests. Consider financial indicators, including years in business (showing stability), ownership structure and investment in capabilities, customer diversity (avoiding dependence on a single customer), and financial health indicators, if available.

Strategic alignment evaluates whether the partnership makes strategic sense for both parties through scale compatibility where your business is significant enough for attention but not so large as to dominate the partner’s capacity, market focus and industry expertise relevant to your products, technology roadmap alignment showing investment in relevant capabilities, and growth trajectory compatible with your plans.

Be cautious about partners where your business would represent an overwhelming portion of their capacity—your growth might exceed their ability to scale. Conversely, ensure your volumes are sufficient to warrant appropriate attention. The ideal partner views your business as strategically important and worth investing in.

The Selection Process: From Evaluation to Partnership

Effective partner selection follows a structured process that balances thorough evaluation with reasonable timeframes. A typical process includes defining requirements documenting technical needs, volumes, quality requirements, and other criteria, identifying candidates through research, referrals, and industry knowledge, issuing requests for quotation providing detailed specifications and requirements, evaluating proposals against predetermined criteria with cross-functional team input, conducting site visits to leading candidates, checking references with current customers, negotiating terms including pricing, payment terms, intellectual property protection, and quality requirements, and starting with pilot projects before committing full production.

The pilot project approach de-risks new partnerships by validating capabilities, communication, and quality performance with real production before committing your entire product portfolio. A successful pilot builds confidence and reveals any issues when correction is straightforward.

Managing the Partnership for Ongoing Success

Partner selection is just the beginning. Successful partnerships require ongoing managementto ensureg alignment,addressg issues promptly, anddriveg continuous improvement. Best practices include regular business reviews assessing performance, discussing challenges, and planning improvements, performance metrics tracking quality, delivery, and cost performance, collaborative problem-solving working together when issues arise rather than assigning blame, design collaboration involving the partner in new product development, continuous improvement initiatives identifying optimization opportunities, and communication maintaining open channels at multiple organizational levels.

The most successful partnerships evolve beyond transactional relationships into strategic collaborations where both parties invest in mutual success. Your EMS partner should be an extension of your organization, contributing expertise and capability that enhance your competitive position.

Regional Considerations: The Case for European Manufacturing

Geographic location is an essential criterion for partner selection. While Asia-Pacific has traditionally dominated electronics manufacturing, European manufacturing offers compelling advantages for companies serving European markets including dramatically shorter lead times with freight measured in days rather than weeks, reduced inventory requirements enabled by shorter supply chains, lower logistics costs avoiding transcontinental shipping, enhanced responsiveness for product changes or issue resolution, reduced supply chain risk from shorter, simpler logistics, and regulatory alignment with European standards and compliance requirements.

For companies serving pan-European markets from the UK to Scandinavia to Central Europe, manufacturing in locations like Poland provides a central position, enabling efficient distribution. The combination of skilled workforce, modern infrastructure, competitive costs, and European Union membership makes Central European manufacturing increasingly attractive for companies reconsidering traditional Asian sourcing.

Conclusion: Integrating Cost Optimization and Partner Selection

Cost optimization and partner selection are not separate activities; they are deeply interconnected strategic decisions. The right manufacturing partner brings not just competitive pricing but also expertise in BOM optimization, DFM guidance, supply chain management, quality systems, and continuous improvement, collectively delivering superior total cost outcomes. Conversely, even the most sophisticated internal cost-optimization efforts can be undermined by an inadequate manufacturing partner that lacks the capabilities, systems, or commitment to execute effectively.

Leading companies approach these decisions holistically, recognizing that true optimization requires both internal discipline in design and component selection and external collaboration with manufacturing partners who add strategic value beyond assembly. The framework presented here—comprehensive cost analysis, systematic BOM optimization, effective manufacturing processes, and rigorous partner evaluation—provides the foundation for decisions that enhance both profitability and competitive position.

In an increasingly competitive global market where product lifecycles compress and supply chains face ongoing disruption, companies that master strategic cost optimization and build strong partnerships with capable, aligned manufacturing partners will possess a decisive advantage. The investment in thorough cost analysis and careful partner selection pays dividends throughout product lifecycles, including lower costs, higher quality, faster time-to-market, reduced risk, and, ultimately, a stronger competitive position. Whether you’re developing your first product or optimizing an established portfolio, applying these principles systematically will drive better outcomes and stronger business performance.