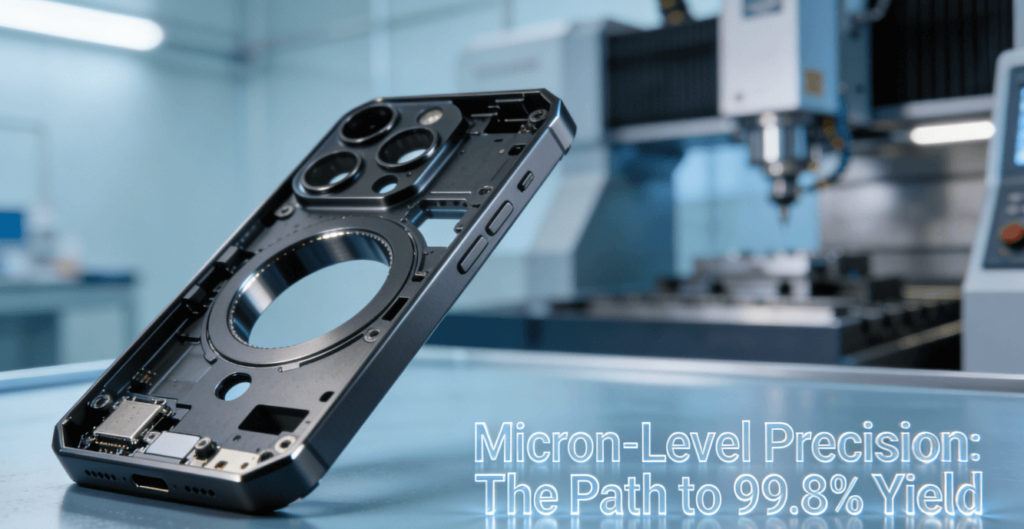

Figure 1: DFM serves as a critical bridge, integrating design intent with manufacturing capabilities to eliminate production errors proactively.

Introduction

Precision engineers are faced with costly problems as they attempt to convert designs into manufacturable things. Misinterpretations in designs, like wrong tolerances, posed problems as they intensified with large scale production.

The Design for Manufacturing, or DFM, method tackles these issues before they become problems. By incorporating knowledge about manufacturing at an early stage, DFM prevents production errors and serves as a vital bridge for products with ambitious goals to be high-quality and affordable. This tutorial will guide you through DFM and its best practices.

What Are the Most Common (and Costly) Production Errors in Precision Engineering?

Precision Engineering Definition error production. Errors in precision engineering definition include more error considerations beyond shop-floor production. Generally, they result because a design would be un-manufacturable. Awareness about production error costs begins with implementation of DFM.

Unusually Tight or Incorrectly Applied Tolerances

A strategy with an “the tighter, the better” philosophy could potentially see machining times escalade dramatically and rates of product generation slump drastically. The need for tight tolerances demands more precise machining tools and lower feed rates. It is very essential to adhere to standards like ASME Y14.5. To learn more, see: ASME Y14.5 Standard.

Difficult-to-Machine Features

It includes components with deep holes and large aspect ratios, which may suffer from drilling drift and breaking, components with internal sharp corners that may need special tools or EDM machining, and components with thin walls that might vibrate and bend as they are being machined.

Ignoring Post-Processing Needs

Creating without consideration for secondary processing needs, anodizing, plating, and bead blasting. A recess, for instance, may not be suited for uniform plating.A feasibility analysis conducted on the production process at the product design stage can be useful in overcoming these common Production Errors.

How does DFM serve as a proactive approach against these risks?

“Prevention instead of correction” thus represents the fundamental philosophy on which DFM is based. It is not an end-of-cycle audit process but, instead, an integrated methodological approach that is adopted within its design philosophy.

It becomes clear why proactive strategy advantage is required by comparing project schedules. Cost escalation becomes high if changes are incorporated at a latter stage in traditional developments. But with DFM, even though initial overheads were there in terms of analysis, it ironed out most problems at the stage of drawing board, so cost curves will be smooth with fast time-to-market.

DFM employs simulation tools and knowledge bases to predict challenges related to machining, assembling, and inspections in a virtual representation. Specifically, DFM fosters an attitude of collaborative engineering, with functions like design, manufacturing, and quality engaged early on in a project to achieve an optimal compromise solution among “easy-to-make” and “functional requirements.”

What Does a Structured DFM Process Look Like in Practice?

Professional DFM analysis cannot be done on a superficial level; it needs accuracy and consistency. It might be useful to form a paradigm as follows:

Manufacturability Analysis

This involves a rigorous examination of the design against material properties, the capabilities of advanced equipment like 5-axis CNC machining, and inherent process constraints. At LS Manufacturing, this analysis is supported by a proprietary checklist derived from ISO 9001:2015 certified quality management system, ensuring no potential manufacturability issue is overlooked.

Optimized Solution Output

Providing specific, research-supported recommendations and alternatives for designs. Serving an engineering reason for changes.

Cost and Delivery Re-Evaluation

Providing cost and lead-time estimates based on optimized designs.To comply with guidelines on quality management standards, as per ISO 9001:2015, it will be ensured that a DFM process, as followed above, would be documented. To learn more about it, click here: ISO 9001:2015 Standard.

Figure 2: Applying DFM best practices, such as adding radii and standardizing features, significantly improves manufacturability and reduces cost.

Active DFM Best Practices Regarding CNC Machined Components

To effectively implement concepts of DFM, it is necessary that specific guidelines be followed. Below-mentioned DFM Best Practices relate directly to CNC machining design guidelines, and they pertain to geometry and cost.

Part Geometry Optimizations for Manufacturability

Strategic design for part features greatly promotes machining efficiency and shortens machining time.

- Standardize Internal Radii

The use of a uniform radius for different internal components reduces the number of tool changes needed. Moreover, it leads to lower production cycles and thus costs.

- Deign Self Locating

By incorporating features like datum hole locations or steps into the piece, dependence on more complex and expensive custom-made fixtures can be eliminated. Not only does it make set-up easier, but it also ensures consistency at the end production.

Implementation of Strategic Tolerancing and Processing

It is very important that there be some methodical approach in requirements definition and planning for the production sequence.

- Differentiate Critical and Non-Critical Tolerance

A prime DFM technique would be identifying which dimensions are most important for a given function and specifying tight tolerances solely on these. It should be noted that loosening tolerances on unimportant features can greatly assist in lowering costs.

- Optimize Part Orientation for Machining

How manufacturability can be incorporated into part designs includes thinking about how the part will be supported and machined. The goal is to position the part so as much as possible can be made within a given configuration.

How To Fill The Space That Separates Design and Production for Perfect Implementation?

Perfect Execution requires perfect Design and Manufacturing Collaboration. It will be important for engineers to begin to see manufacturers as problem-solving partners, as opposed to just people who put orders together. All these should begin at the conceptual level with collaboration tools such as joint CAD. Finally, having a partnership with a supplier who has knowledge on CNC machining services and DFM, as that with an experienced firm will make sure that these concepts created on the conceptual stage of product designs will be implemented on the shop floor. To learn more about DFM, check out this tutorial on Design for Manufacturing.

Conclusion

DFM is more than just a cost-control and -management issue and tool. It is an investment method for project success. DFM focuses on error considerations related to production ahead of error occurrence on the production floor. DFM assures project reliability and functionality and enhances project competitiveness. PECs should be knowledgeable about DFM if they have to effectively translate designs into projects.

To learn more about applying DFM on a systematic level on your next project, request your custom DFM solution click on the comprehensive guide to Design for Manufacturing (DFM).

Author Bio

The author leads the engineering team at LS Manufacturing, a specialist in DFM consulting and precision CNC machining services who help aerospace, automotive, and medical device engineers avoid an average of 15-30% in manufacturing costs through proactive design optimization. Our ISO 9001:2015, IATF 16949, and AS9100D certified quality systems guarantee that your project meets the most stringent standards.

FAQs

Q1: Is DFM applicable mainly for large productions?

A: No, because the DFM concepts will be applicable at all volumes. Regarding prototypes, it will result in faster turn-around times and will help obtain valid testing. At low volumes, it will provide optimal unit cost. ROI will be very high.

Q2: To what extent will there be cost savings from DFM implementation.

A: Cost savings can vary based on project complexity. Nevertheless, cost savings ranging from 15-30% per unit can be realized via manufacturability-optimized designs. Cost savings are realized due to shorter machining cycles and waste generation.

Q3: Does DFM analysis increase the product development period?

A: It not only brings an extra phase at the start of the process (usually 1-2 days), but it also reduces greatly the production time for making designs and changes, as well as problem-solving.

Q4: Do I have to have a manufacturing partner to do my own DFM analysis?

A: It can be done internally, but it would be greatly advantageous to have an experienced manufacturer. Not only will they be knowledgeable about your specific market and goals but also about various industries they have worked with.

Q5: Which file formats and what type of data are required for a professional review on DFM?

A: It requires some standard set of 3D CAD files, either STEP or SLDPRT, and some detailed briefing on what it should do and what it should be made of. The more information available, the more specific and detailed DFM analysis will be.

Read More Gorod