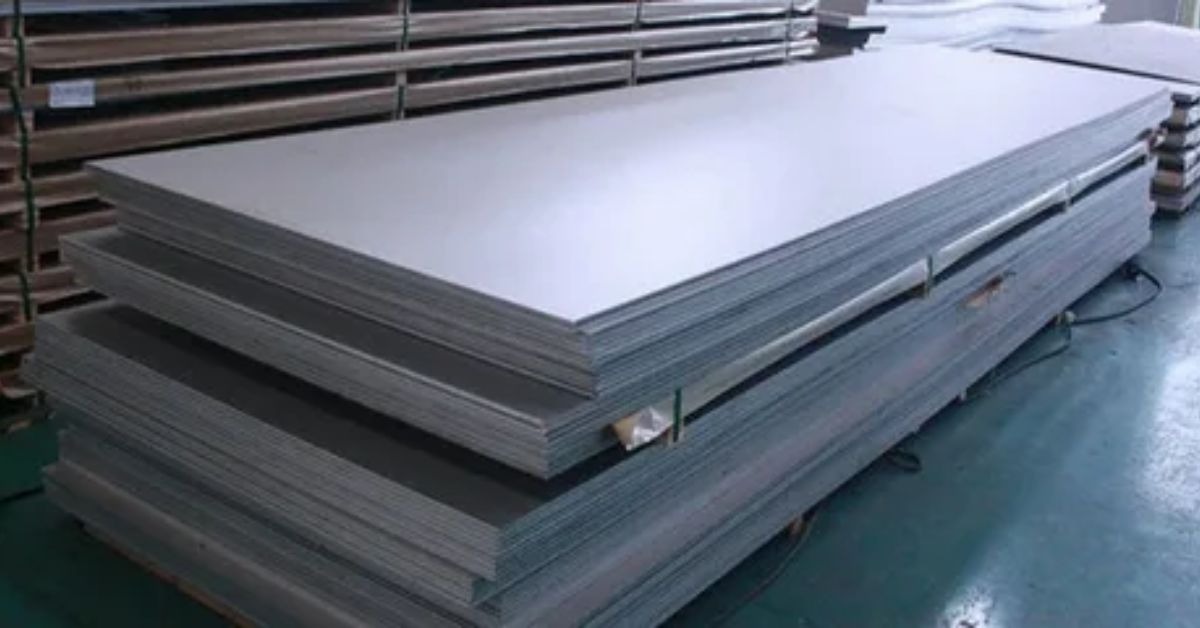

Stainless steel 316 is a high-quality alloy that is incredibly strong and resistant to corrosion. It has molybdenum unlike the normal stainless steel and hence is suitable in harsh environments. Concisely, it is the material to adopt when durability and reliability are the most important.

It is a common stainless steel that is used in various industries, both in the medical field and in the sea. It is popular among both engineers and manufacturers because of its capacity to withstand rust, chemicals, and extreme temperatures. The thing is, though, that its effects on contemporary production are far more than simply toughness.

Due to its special features, 316 stainless steel is transforming the way products are drawn and manufactured. Firms can make durable and high-performance products that require minimal maintenance and replacements. Wonder how this material is changing the future of manufacturing? Let’s dive in and find out.

What Is 316 Stainless Steel?

316 stainless steel is a high-grade alloy that is known to be very tough, strong, and also resistant to rust and corrosion. It is a bit more specific to standard stainless steel due to the addition of molybdenum, which enhances its resistance to operating in extreme conditions. This is because it is an ideal preference to industries that think more of performance and longevity.

The high-grade stainless steel is everywhere, in marine devices and chemical plants, medical devices and in the kitchen. Its functionality and robustness make it an actual revolution in contemporary production. In a nutshell, High-grade stainless steel sounds reliable and it is a test of time.

Key Properties Driving Modern Manufacturing

In modern manufacturing, 316 stainless is being hailed for its qualities, that it is a superstar. Its high corrosion resistance and durability imply that machines, tools and equipment last longer with minimum maintenance. They also enable manufacturers to develop complex products that work efficiently in rough environments.

Not only is it tough, but premium stainless steel can also take the heat and even the chemicals. It is simple to handle in the process of fabrication and welding which saves time and costs. It is not surprising that industries in all corners turn to it to take innovation and efficiency to a new level.

Key Properties of 316 Stainless Steel:

- Increased anti-rust and corrosion.

- Strongness of heavy-duty use.

- Superior heat and chemical resiliency.

- Withstands harsh environmental conditions.

- Easy to weld, cut, and shape

- Extended life with few servicing requirements.

How 316 Stainless Steel Is Changing the Manufacturing Game

316 is changing the current manufacturing process by allowing companies to produce stronger and more durable products with minimal effort. Its resistance to corrosion, chemicals, and heat translates to reduced breakdowns and downtime, leading to smooth production lines. Manufacturers can explore more advanced designs without fearing material failure.

This substance is not only hard, but it is making industries to be efficient and sustainable. Reduced waste due to longer product lifespans and time and money saved due to easier fabrication. Simply put, premium stainless steel will be instrumental in driving manufacturing into a smarter, more innovative phase.

Major Applications in Modern Manufacturing

The toughness and reliability of 316 stainless steel have seen it find extensive application in many industries. It keeps medical tools, food processing equipment, and products safe, hygienic and long-lasting. Its capacity to avoid corrosion and wearability makes it a reliable material, which is used in high-performance applications.

It is not only about durability, but premium stainless steel also assists the manufacturers in making innovative designs without fear of failure of the material. In the sea, on a chemical plant or an industrial machine, this alloy keeps everything in the production running well and smoothly.

Major Applications of 316 Stainless Steel:

- Kitchen equipment and processing of food.

- Medical equipment and surgery tools.

- Offshore and marine equipment.

- Machinery: chemical and pharmaceutical.

- Structural and architectural elements.

- Machinery and manufacturing instruments.

Advantages Over Other Stainless Steels

The type of stainless steel known as 316 is better than the other types of stainless steel as it has better resistance to corrosion and durability. Though ordinary stainless steel can fail under harsh or salty conditions, 316 stainless steel makes products resilient and strong with time. This makes it one of the best when longevity is the most important factor in industries.

In addition to Corrosion resistance, premium stainless steel is less difficult to fabricate and to weld. It enables manufacturers to develop complicated components without fear of cracking or weakening. The minimal increase in cost has long-term performance and maintenance in most instances, compensated for the slight increase in cost upfront.

Superior Corrosion Resistance

The stainless resists are 316 and resist rust and chemicals much better than other stainless steels as well as salt water. This is suitable in marine, chemical and food-processing industries where conditions are unfriendly. It is more durable and cost-effective and efficient in terms of components.

High Durability and Strength

The 316 stainless steel can withstand greater mechanical stress and extreme temperatures as compared to the normal grades. The advantage of this is that it is ideal in heavy-use applications, industrial equipment, and structural members that have to work day in and day out.

Fabrication and Welding Ease

Compared with other high-grade steels, premium stainless steel is easier to cut and shape and also to weld. Producers can produce detailed designs or elaborate components with little chance of failure of materials, enhancing the productivity and versatility on the production floor.

Long-Term Cost Benefits

Despite the fact that the initial cost of premium stainless steel could be a bit more expensive, the longer life span will lead to lower replacement and maintenance expenses. Overall, it can save the businesses money, time and headaches in the long term due to investing in this material.

Conclusion

The 316 stainless steel is not merely a material, but a game-changer in contemporary manufacturing. Its ability to withstand, being corrosive and being easily fabricated enables industries to produce long-lasting and quality products. It ensures a smooth and reliable production of medical equipment, marine equipment, etc.

The use of high-grade stainless steel offers efficiency, cost-saving, and flexibility to innovative designs for manufacturers. Its resistance to extreme weather and low-maintenance requirements also make it an investment that would be worth it in the long term. Indeed, premium stainless steel is defining the future of manufacturing, one project at a time.