In the modern industrial and manufacturing world, precision Repmold, efficiency, and safety have become non-negotiable. One of the most crucial elements in this sector is the ability to create and manage molds effectively. Molds are the foundation of countless products, from automotive parts to household tools, and the technology behind mold-making has seen drastic advancements over the years. Among the new breakthroughs, has emerged as a revolutionary solution. It combines speed, safety, and intelligence, redefining how mold production and management are handled across industries. The rise of reflects a shift toward smarter technologies that do not just save time but also enhance accuracy, reduce waste, and make industrial processes safer for operators and the environment.

What is Repmold

Repmold is a next-generation mold technology that integrates advanced engineering techniques with cutting-edge digital tools to deliver efficient and sustainable mold-making solutions. Unlike traditional methods, which can be time-consuming and often lack precision, focuses on creating molds that are adaptable, faster to produce, and easier to maintain. It is designed with a strong emphasis on safety, ensuring that the risks often associated with mold production are significantly minimized. technology has become popular among manufacturers who seek not just speed but also reliability and cost-effectiveness in their operations.

The Importance of Mold Technology in Modern Industries

Mold technology is an unseen hero in today’s production landscape. Almost every product we use daily, from plastic bottles and car dashboards to medical devices and electronics casings, originates from a mold. Without accurate and durable molds, the process of mass production would be nearly impossible. This highlights the critical role technologies like Repmold play in modern industries. By optimizing mold creation, ensures that businesses can scale production, maintain consistent quality, and minimize errors. In industries where precision is vital—such as automotive, aerospace, and healthcare—provides a dependable foundation for innovation.

How Repmold Ensures Faster Production

Time is one of the most valuable resources in any manufacturing setup. Traditional mold-making methods often take weeks or even months to design, test, and finalize. Repmold addresses this challenge by integrating smart software, automation, and digital simulations. These tools allow engineers to design molds quickly, test them virtually, and refine them before actual production begins. This reduces trial-and-error stages and cuts down on unnecessary delays. By accelerating mold production, helps manufacturers respond faster to market demands, launch products on time, and maintain a competitive edge in fast-moving industries.

Safety Features of Repmold Technology

One of the greatest advantages of Repmold is its emphasis on safety. Mold-making has historically been associated with risks such as equipment malfunctions, exposure to hazardous materials, and accidents during manual handling. incorporates advanced safety protocols, automated handling systems, and intelligent monitoring features to reduce such risks. Its design minimizes human intervention in high-risk stages, making the entire process safer for operators. This not only protects the workforce but also reduces costly downtime that can arise from workplace accidents. Safety has become a cornerstone of, making it a preferred choice for industries that prioritize worker welfare.

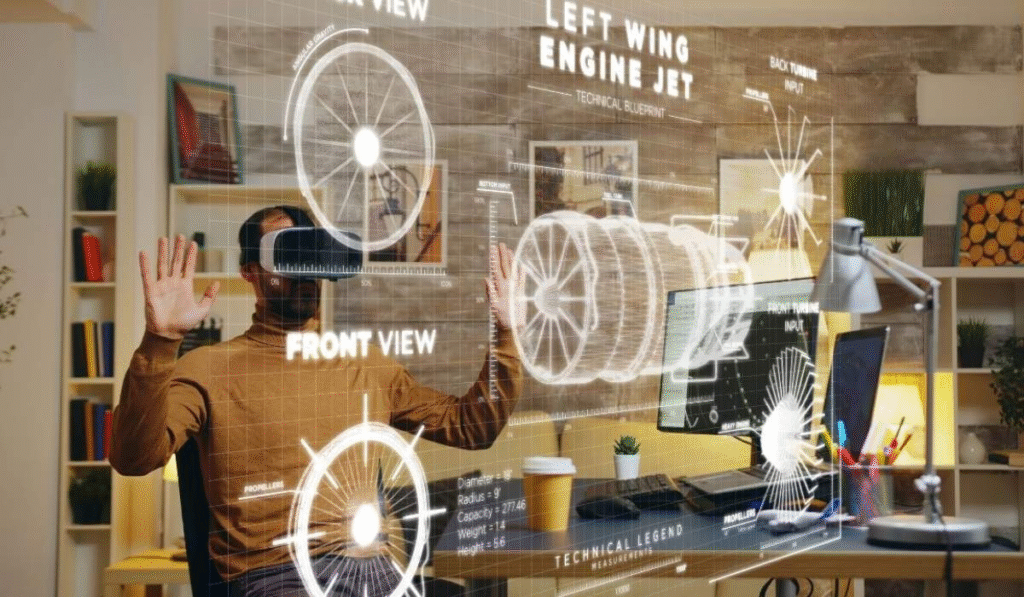

Smart Features and Digital Integration

Repmold is not just about speed and safety—it is also about intelligence. This technology leverages smart features such as predictive maintenance, AI-driven monitoring, and real-time data analytics. For example, sensors within the molds can monitor stress, wear, and performance, sending alerts when maintenance is needed. This predictive approach prevents unexpected breakdowns, saves repair costs, and extends the lifespan of the molds. The integration of digital platforms allows manufacturers to connect their mold-making processes with broader production systems, enabling seamless coordination and efficiency. With, industries gain the benefit of smart manufacturing, where every step is optimized through data-driven insights.

Benefits of Repmold for Manufacturers

The benefits of adopting Repmold technology are vast and transformative. First, it reduces lead times, allowing manufacturers to deliver products to market more quickly. Second, it enhances product quality by ensuring molds are precise, consistent, and durable. Third, it promotes cost savings by minimizing material waste, reducing the need for frequent mold replacements, and preventing expensive downtime. Additionally, supports sustainable practices by cutting down energy consumption and aligning with eco-friendly manufacturing goals. Overall, it offers a comprehensive package that helps industries remain competitive while also adopting responsible production practices.

Applications of Repmold in Various Sectors

Repmold has wide-ranging applications across multiple sectors. In the automotive industry, it is used to design and produce complex parts with high precision. In the medical field, ensures the creation of accurate molds for devices that require stringent safety standards. The electronics industry benefits from by producing casings and components that must meet both functional and aesthetic requirements. Even in consumer goods, where large-scale production is common, provides the speed and reliability needed to keep up with demand. Its adaptability makes it a universal solution for industries that depend heavily on mold-based production.

The Future of Mold Technology with Repmold

As industries continue to embrace automation and digital transformation, Repmold is positioned as the future of mold technology. It represents a step toward fully automated, intelligent, and sustainable manufacturing systems. With continuous research and innovation, is expected to become even more advanced, incorporating features like machine learning algorithms for automatic mold optimization and integration with green energy sources. The future of mold technology will likely be defined by solutions like, which combine human ingenuity with digital precision to create smarter and safer industrial ecosystems.

Conclusion

Repmold stands as a groundbreaking development in the field of mold-making technology. By combining speed, safety, and intelligence, it addresses the core challenges that manufacturers face in today’s competitive market. Its ability to deliver faster production, safer operations, and smarter monitoring makes it an indispensable tool across industries. The adoption of is not just a step toward improved efficiency but also a commitment to sustainability and workplace safety. As industries move forward into a future dominated by automation and data-driven processes, will continue to shape the way products are made, setting a new standard for innovation in mold technology.

Frequently Asked Questions

1. What is Repmold?

- Repmold is an advanced mold technology designed to improve the speed, safety, and efficiency of mold production in modern industries.

2. How does Repmold improve manufacturing speed?

- Repmold uses digital design, simulation, and automation to reduce production time and eliminate unnecessary trial-and-error stages.

3. What industries benefit most from Repmold?

- Industries such as automotive, medical, electronics, and consumer goods benefit the most from Repmold due to their reliance on precise and efficient mold-making.

4. Is Repmold a safe technology for operators?

- Yes, Repmold incorporates automated systems and advanced safety features that minimize human exposure to high-risk tasks, ensuring safer operations.

5. What makes Repmold different from traditional mold-making methods?

- Unlike traditional methods, Repmold emphasizes digital integration, predictive maintenance, and sustainability, making it more efficient and cost-effective.