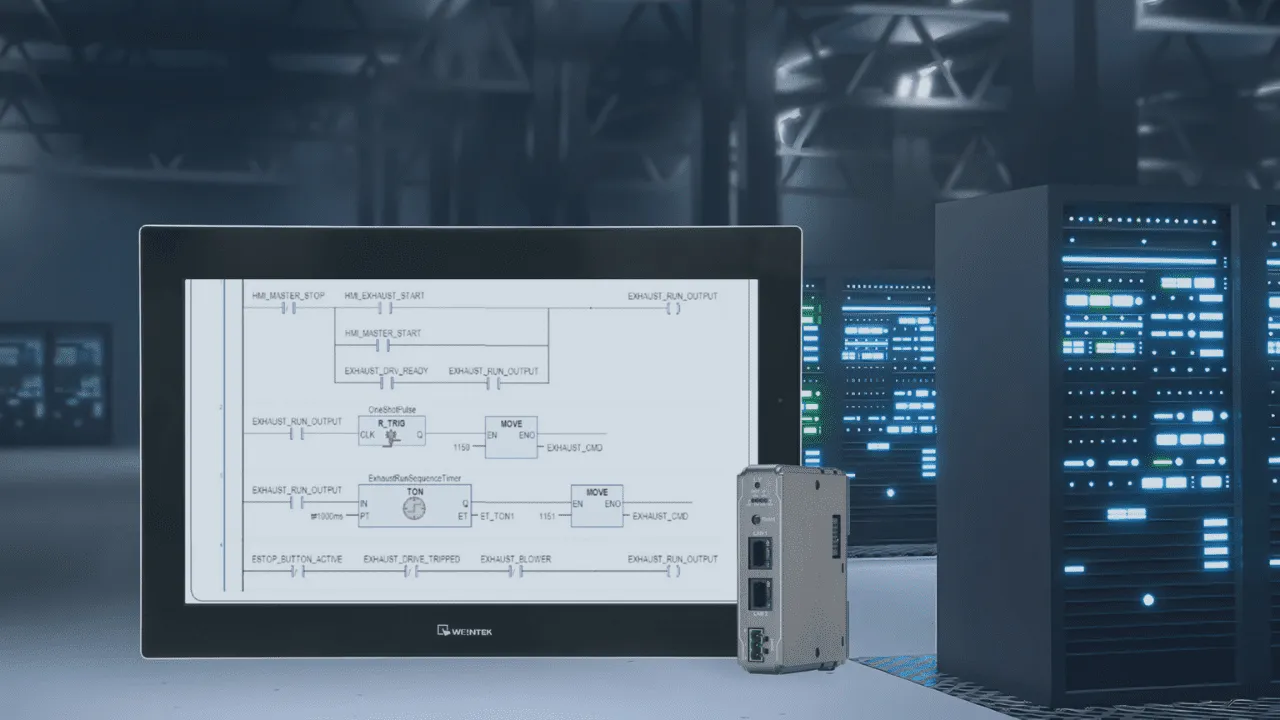

Modern industrial automation depends on seamless communication between operators and machinery. Human Machine Interfaces (HMI) and Remote Input/Output (I/O) systems serve as the critical bridge that makes this communication possible, enabling efficient monitoring, control, and data collection across manufacturing environments.

HMI Display & Remote I/O Solutions have evolved from simple control panels to sophisticated touchscreen systems that integrate with complex network architectures. These technologies allow operators to interact with automated processes while Remote I/O modules extend control capabilities to distant locations within a facility or across multiple sites.

Understanding how these systems work together can transform your operational efficiency and provide the foundation for smart manufacturing initiatives. Whether you’re upgrading legacy equipment or designing new automation systems, the right HMI and Remote I/O configuration can streamline operations and improve productivity.

What Are HMI Display Solutions?

Human Machine Interfaces represent the visual and interactive layer between operators and automated systems. These displays provide real-time data visualization, alarm management, and control capabilities through intuitive touchscreen interfaces.

Modern HMI displays offer high-resolution graphics, multi-language support, and customizable layouts that adapt to specific operational needs. They can display process variables, system status, historical trends, and maintenance schedules all within a single, user-friendly interface.

Key Features of Modern HMI Systems

Touchscreen Technology: Contemporary HMI displays utilize capacitive and resistive touchscreen technology that responds accurately to operator input, even in harsh industrial environments with gloves or protective equipment.

Data Visualization: Advanced graphical capabilities allow complex process data to be presented through charts, graphs, gauges, and animated graphics that make information easily interpretable at a glance.

Alarm Management: Integrated alarm systems provide immediate notification of system anomalies, equipment malfunctions, or process deviations, enabling rapid response to maintain operational continuity.

Recipe Management: Many HMI solutions include recipe or parameter storage capabilities, allowing operators to quickly switch between different production settings or product configurations.

Understanding Remote I/O Solutions

Remote I/O systems extend the reach of control systems by placing input and output modules closer to field devices, reducing wiring costs and improving system reliability. These distributed systems collect data from sensors and control actuators across extended areas.

The architecture typically consists of a main controller communicating with remote I/O modules through industrial communication protocols. This distributed approach offers flexibility in system design and simplifies maintenance procedures.

Benefits of Remote I/O Implementation

Reduced Wiring Costs: By positioning I/O modules near field devices, Remote I/O systems significantly decrease the amount of cable required, lowering both material and installation costs.

Enhanced System Reliability: Distributed I/O architecture reduces single points of failure and allows for redundant communication paths, improving overall system uptime.

Simplified Troubleshooting: Modular design enables technicians to isolate and address issues quickly without affecting the entire system operation.

Scalability: Remote I/O systems can be easily expanded as operational requirements grow, accommodating additional sensors, actuators, or control points.

Integration Advantages of Combined HMI and Remote I/O

When HMI Display & Remote I/O Solutions work together, they create a comprehensive automation platform that maximizes operational visibility and control flexibility. This integration enables centralized monitoring of distributed processes.

The combination allows operators to view and control remote processes from a central location while maintaining the ability to access local controls when needed. Data from remote I/O modules flows seamlessly to HMI displays, providing complete system awareness.

Communication Protocols and Connectivity

Modern systems support multiple communication protocols including Ethernet/IP, Modbus TCP/RTU, PROFINET, and others. This protocol diversity ensures compatibility with existing equipment while providing upgrade paths for future expansion.

Wireless communication options extend connectivity to areas where cable installation is impractical or cost-prohibitive. These solutions maintain industrial-grade reliability while offering installation flexibility.

Applications Across Industries

Manufacturing: Production lines benefit from distributed I/O for machine control combined with operator stations featuring HMI displays for process monitoring and quality control.

Water Treatment: Remote I/O modules monitor pumps, valves, and sensors across treatment facilities while HMI systems provide centralized control and reporting capabilities.

Oil and Gas: Distributed control architecture enables monitoring of remote wellheads and pipeline equipment with centralized operator interfaces for system oversight.

Building Automation: HVAC systems utilize Remote I/O for zone control and sensor monitoring, integrated with HMI displays for facility management and energy optimization.

Selection Criteria for HMI Display & Remote I/O Solutions

Environmental Considerations

Industrial environments present unique challenges including temperature extremes, moisture, vibration, and electromagnetic interference. Equipment selection must account for these conditions to ensure reliable operation.

IP ratings, operating temperature ranges, and shock/vibration specifications should align with installation environments. Chemical resistance and UV stability may be important factors for outdoor or harsh chemical environments.

Performance Requirements

System response times, data throughput, and processing capabilities must match application demands. Real-time control applications require faster update rates than simple monitoring systems.

Memory capacity affects the complexity of graphics, data logging capabilities, and program storage. Network bandwidth determines the amount of data that can be transmitted between remote I/O modules and central controllers.

Future Expansion Planning

Modular system architectures accommodate growth without requiring complete system replacement. Consideration of future I/O requirements, communication needs, and processing demands helps avoid costly upgrades.

Protocol compatibility ensures that new equipment can integrate with existing systems. Open communication standards provide the greatest flexibility for future expansion and equipment selection.

Implementation Best Practices

System Architecture Planning: Design communication networks with appropriate redundancy and bandwidth to handle current and anticipated future data loads.

Security Considerations: Implement cybersecurity measures including network segmentation, access controls, and regular security updates to protect industrial control systems.

Documentation and Training: Comprehensive system documentation and operator training ensure effective utilization and maintenance of HMI and Remote I/O systems.

Testing and Commissioning: Thorough testing of all system components and communication paths validates proper operation before production deployment.

Maximizing Your Automation Investment

HMI Display & Remote I/O Solutions represent foundational technologies that enable modern industrial automation. Their successful implementation requires careful planning, appropriate equipment selection, and consideration of both current needs and future expansion requirements.

The integration of these technologies creates opportunities for improved operational efficiency, reduced maintenance costs, and enhanced system reliability. As manufacturing continues evolving toward Industry 4.0 concepts, HMI and Remote I/O systems provide the infrastructure necessary for data-driven decision making and advanced analytics.

Investing in quality HMI Display & Remote I/O Solutions positions your operation for both immediate productivity gains and long-term competitive advantages in an increasingly automated industrial landscape.

Read More Gorod