Introduction to Concrete Workability

Concrete is one of the most essential materials used in construction, yet its performance depends greatly on its fresh-state properties before it hardens. Among these properties, workability plays a central role because it determines how easily concrete can be mixed, transported, placed, compacted, and finished without segregation. To understand and control workability on construction sites, engineers rely on simple but effective testing methods. One of the most widely recognized and applied methods is the slump test, which helps engineers define concrete slump in a measurable and repeatable way. This test has become a standard quality-control tool across residential, commercial, and infrastructure projects worldwide.

Understanding the Concept of Concrete Slump

To define concrete slump, it is necessary to understand what happens to concrete immediately after mixing. Fresh concrete behaves like a semi-fluid material whose consistency changes depending on the water content, aggregate grading, cement type, and admixtures. Slump refers to the vertical settlement or subsidence of concrete when it is released from a standard mold. This settlement indicates how fluid or stiff the concrete mix is. When engineers define concrete slump, they are essentially describing the consistency of the mix in terms of its ability to flow under its own weight without external vibration.

Purpose of the Concrete Slump Test

The main objective of the slump test is to assess the uniformity and workability of freshly mixed concrete. Construction teams use this test to ensure that the concrete delivered to the site matches the design specifications and remains consistent across batches. When professionals define concrete slump, they gain a quick indication of whether the concrete is too dry, too wet, or within the acceptable range. This allows immediate corrective actions, such as adjusting water content or rejecting unsuitable concrete, which helps prevent structural defects and long-term durability issues.

Equipment Used in the Slump Test

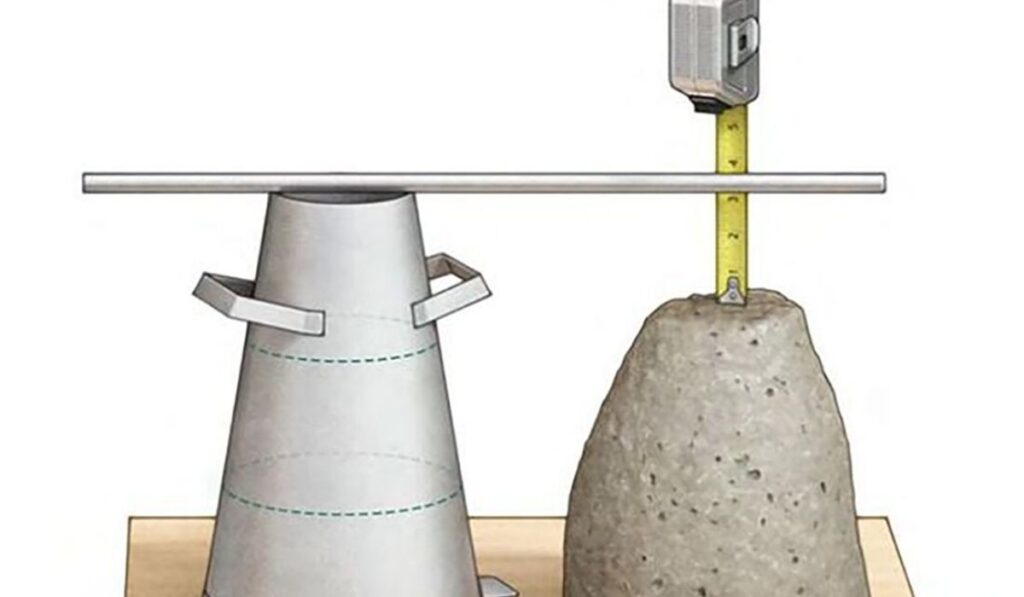

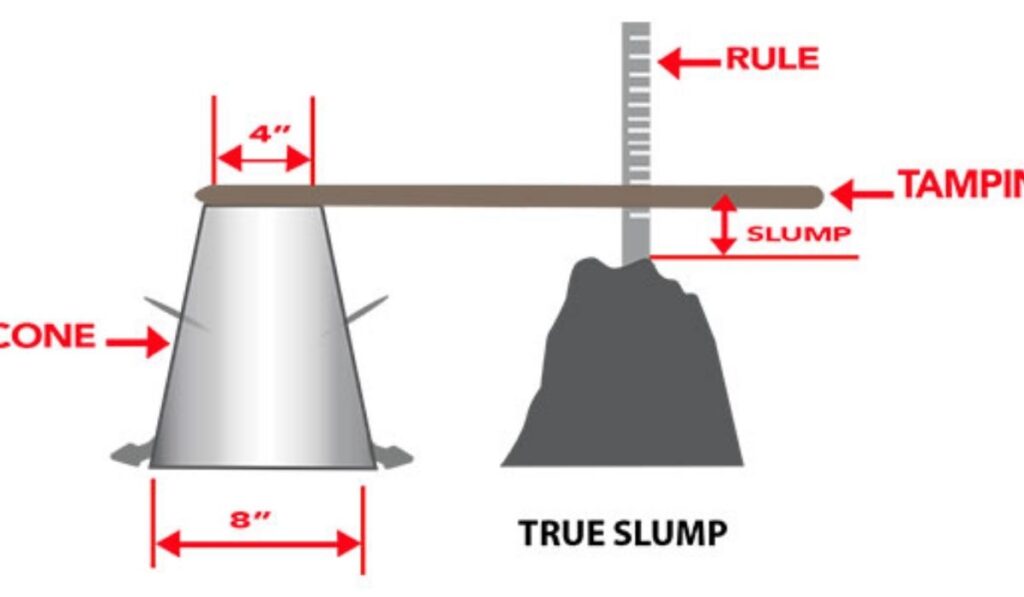

The equipment required for performing a slump test is simple, portable, and inexpensive, making it ideal for on-site quality checks. The primary component is a slump cone, also known as an Abrams cone, which has a standardized shape and dimensions. Along with the cone, a tamping rod, a rigid base plate, and a measuring scale are used. These tools help engineers define concrete slump accurately by ensuring that the test conditions remain consistent every time it is conducted, regardless of location or project size.

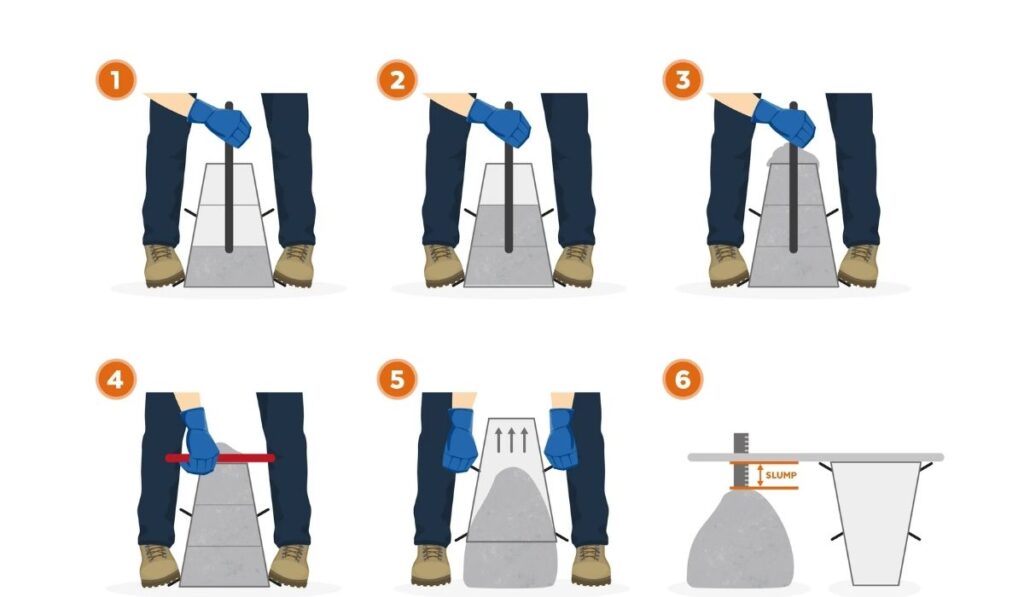

Procedure of Conducting a Concrete Slump Test

The procedure of the slump test follows a standardized method to maintain reliability. Fresh concrete is placed into the slump cone in layers, each layer being compacted uniformly using the tamping rod. Once the cone is filled and leveled, it is carefully lifted upward, allowing the concrete to settle freely. The reduction in height of the concrete is then measured. This measured difference is used to define concrete slump in millimeters or inches, depending on regional standards, offering a direct representation of the mix’s workability.

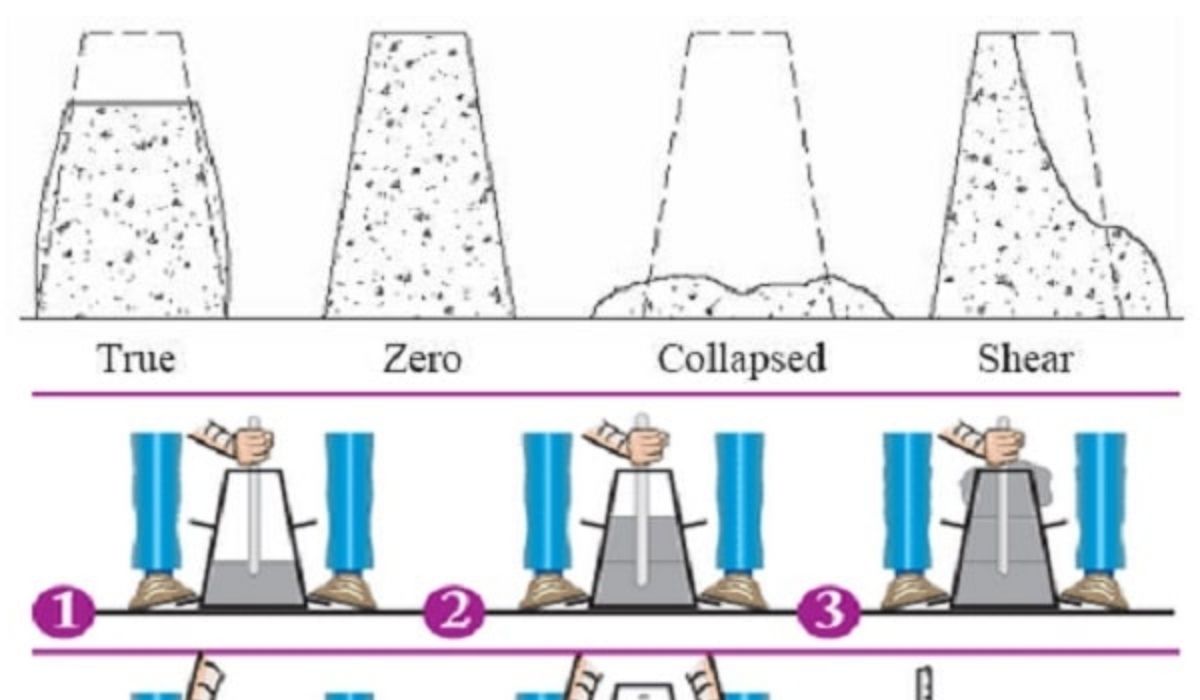

Types of Concrete Slump

When observing the behavior of concrete after removing the slump cone, different slump patterns may occur. A true slump indicates uniform settlement and is considered desirable. A shear slump suggests a lack of cohesion, where part of the concrete slides sideways, indicating potential segregation. A collapse slump occurs when the concrete is overly wet and loses its shape entirely. These patterns help engineers define concrete slump behavior and identify whether the mix design or batching process requires adjustment.

Factors Affecting Concrete Slump

Several variables influence slump values, making it important to interpret results carefully. Water content is the most significant factor, as even small changes can dramatically affect consistency. Aggregate size, shape, and grading also play a crucial role, along with cement content and temperature. Chemical admixtures such as plasticizers can increase slump without adding water. Understanding these factors allows professionals to define concrete slump more accurately while maintaining strength and durability requirements.

Importance of Slump Control in Construction

Proper slump control ensures that concrete can be placed efficiently while achieving the desired structural performance. If the slump is too low, concrete becomes difficult to work with, leading to poor compaction and honeycombing. If the slump is too high, excessive water can weaken the hardened concrete and increase shrinkage and cracking. By learning how to define concrete slump correctly, construction teams can strike the right balance between workability and strength, ensuring long-lasting and safe structures.

Standards and Specifications for Slump Testing

Slump testing is governed by international standards to ensure consistency and reliability. Organizations such as ASTM, ACI, and EN provide guidelines on acceptable slump ranges for different applications. These standards help engineers define concrete slump according to project requirements, whether it is for foundations, pavements, columns, or high-rise structures. Adhering to these specifications ensures compliance with building codes and enhances overall construction quality.

Limitations of the Concrete Slump Test

Despite its widespread use, the slump test has certain limitations. It is most effective for conventional concrete mixes and may not accurately represent workability for highly flowable or self-compacting concrete. Additionally, the test does not directly measure strength or durability. However, when combined with other quality-control methods, the ability to define concrete slump remains a valuable indicator of fresh concrete performance on-site.

Role of Concrete Slump in Quality Assurance

Quality assurance in construction relies heavily on routine testing and documentation. Slump testing provides immediate feedback, allowing adjustments before concrete placement proceeds. When engineers consistently define concrete slump throughout a project, they can maintain uniformity across multiple pours, reduce material waste, and minimize costly repairs. This proactive approach contributes significantly to project efficiency and structural reliability.

Applications of Concrete Slump Test in Modern Construction

The slump test is used in a wide range of construction projects, from small residential buildings to large-scale infrastructure developments. It is particularly useful in ready-mix concrete operations, where maintaining consistency during transportation is critical. By using the slump test to define concrete slump at delivery points, contractors can verify that the concrete remains within acceptable limits despite variations in travel time and environmental conditions.

Final Thoughts on Concrete Slump Testing

Understanding how to define concrete slump is fundamental for anyone involved in concrete construction. The slump test provides a simple yet effective way to evaluate workability, maintain quality, and prevent common construction issues. While it is not a comprehensive measure of concrete performance, it remains an indispensable tool in everyday construction practice. For deeper technical background and historical context, you can explore additional information through this anchor on define concrete slump: Slump_test.

Frequently Asked Questions

1. What does concrete slump indicate?

- It indicates the workability and consistency of fresh concrete.

2. Why is slump testing done on-site?

- To ensure concrete meets design and quality requirements before placement.

3. What is a good slump value for general construction?

- A moderate slump suitable for easy placement without segregation.

4. Can slump affect concrete strength?

- Yes, excessive slump usually reduces strength due to high water content.

5. Is the slump test suitable for all concrete types?

- No, it is mainly used for conventional concrete mixes.