Concrete is one of the most widely used construction materials in the world, concrete slump testing relied upon for everything from small residential projects to large infrastructure developments. Its performance depends not only on its hardened properties but also on the quality of the fresh mix. Before concrete is poured, it is essential to assess its consistency and workability to ensure proper placement, compaction, and finishing. Concrete slump testing is a widely accepted field method that provides an immediate understanding of the mix behavior, helping engineers and construction teams maintain quality and prevent costly errors. Understanding this test is fundamental for achieving durable and safe structures.

Purpose of Concrete Slump Testing

The main purpose of concrete slump test is to evaluate the consistency of fresh concrete. Consistency influences how easily the material can be handled and shaped while maintaining uniformity. Concrete slump testing allows construction professionals to determine whether the mix is suitable for the specific conditions of the project. A mix that is too stiff may be difficult to place and compact, resulting in voids or weak spots. Conversely, a mix that is too wet may compromise the structural strength and lead to excessive shrinkage or cracking. Proper slump control ensures that concrete performs as intended once it hardens.

Understanding Workability in Concrete

Workability is a key property of fresh concrete that describes its ease of placement, consolidation, and finishing. Several factors influence workability, including water content, aggregate shape and size, cement type, and the use of admixtures. Concrete slump testing serves as a practical indicator of workability, giving engineers immediate feedback on the quality of the mix. Maintaining uniform workability ensures consistent compaction, reduces surface defects, and prevents segregation, which ultimately contributes to the strength and durability of the finished structure.

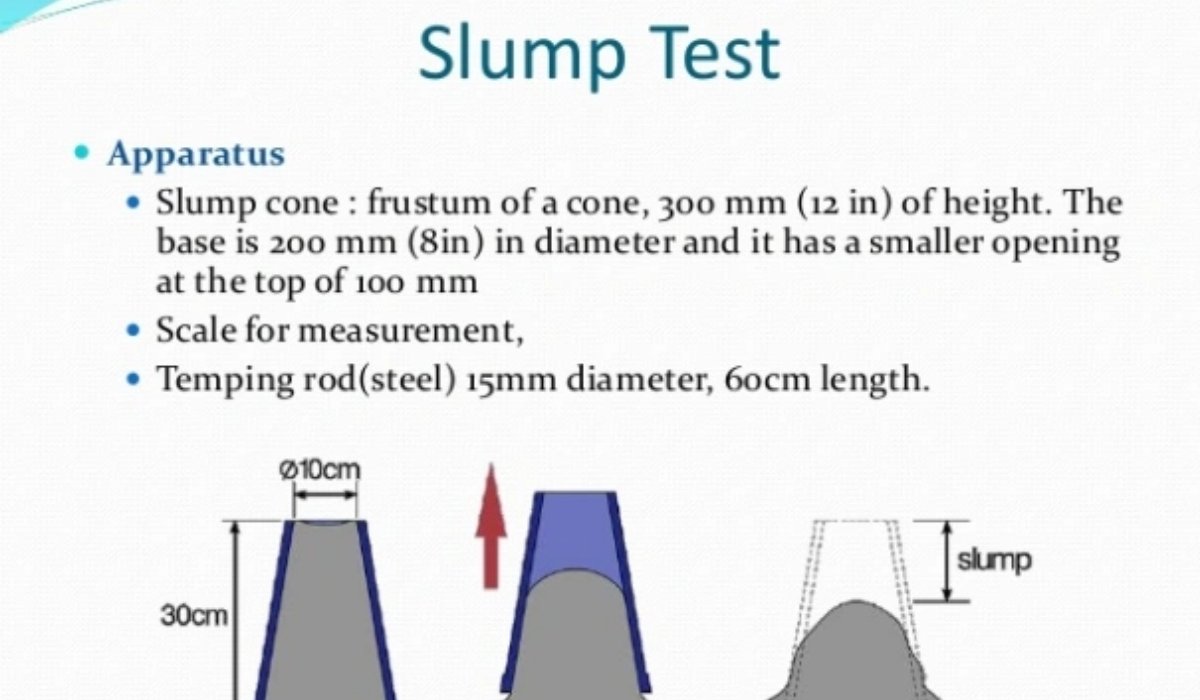

Equipment Needed for Slump Testing

Concrete slump testing requires minimal but precise equipment. The essential tools include a standard slump cone, a tamping rod, and a flat base plate. The cone is filled with freshly mixed concrete in layers, each tamped to remove air pockets. When the cone is lifted, the concrete settles, and the change in height indicates its slump. Proper equipment and technique are critical for accurate measurements. Damaged or improperly sized tools can lead to incorrect readings, affecting quality control decisions and potentially compromising the project.

Procedure for Concrete Slump Testing

The slump test is performed by filling the slump cone in three layers, each approximately one-third of the cone height. Each layer is tamped evenly with a steel rod to eliminate voids. After the cone is removed, the vertical settlement of the concrete is measured to determine the slump value. Concrete slump testing provides quick feedback on the mix’s consistency and allows immediate corrective action if the slump falls outside acceptable limits. The simplicity and speed of the test make it an ideal quality control measure on construction sites.

Types of Slump and Their Significance

Concrete slump testing can reveal different behaviors based on the shape of the settled concrete. A true slump indicates a cohesive and workable mix suitable for standard placement. A shear slump occurs when one side collapses, suggesting poor aggregate grading or inadequate cohesion. A collapse slump, where the concrete completely flattens, typically indicates excessive water content, which can weaken the hardened concrete. By interpreting these slump types correctly, engineers can identify issues early and make adjustments to maintain quality.

Importance of Slump Control

Consistent slump values are critical for achieving predictable performance in concrete structures. Variations in slump can affect finishing techniques, surface appearance, and structural integrity. Concrete slump testing allows teams to maintain control over mix quality during the construction process. Monitoring slump ensures that concrete is placed and compacted efficiently, reducing waste, avoiding defects, and adhering to project specifications. Proper slump control is an essential component of overall quality assurance on construction projects.

Relationship Between Slump and Strength

Although slump testing does not directly measure compressive strength, it is closely linked to the water-cement ratio, which is a key factor in concrete durability. Higher water content increases slump but can reduce strength, increase shrinkage, and cause cracking. Concrete slump testing helps verify that water levels remain within design limits, ensuring the concrete achieves its intended strength and durability. Understanding the relationship between slump and strength allows engineers to make informed decisions about mix adjustments and placement methods.

Limitations of Concrete Slump Testing

Despite its widespread use, concrete slump testing has limitations. The test is less effective for highly flowable mixes such as self-consolidating concrete or extremely stiff mixes with low workability. The accuracy of the test also depends on proper technique, timing, and equipment. Incorrect execution can produce misleading results, which may compromise quality control. Therefore, slump testing is best used in conjunction with other methods, such as air content tests, temperature checks, and compressive strength tests, to ensure comprehensive evaluation of concrete quality.

Quality Assurance and Best Practices

Concrete performance is a cornerstone of quality assurance in construction. Regular testing during placement ensures that each batch meets specified standards. Maintaining detailed records allows teams to identify trends, detect issues in batching, and verify compliance with engineering requirements. Best practices include performing the test immediately after mixing, using calibrated equipment, and following standardized procedures. Combining slump testing with other quality control measures ensures that concrete structures are durable, safe, and perform as expected over time.

Frequently Asked Questions

- What is concrete slump testing?

• Concrete slump testing is a field method used to measure the workability and consistency of freshly mixed concrete. - Why is concrete slump testing important?

• It ensures that the concrete mix meets project specifications and can be placed, compacted, and finished properly. - How is concrete slump testing performed?

• The test involves filling a standard slump cone with fresh concrete, tamping it, and measuring the amount it settles. - Can concrete slump testing detect mix inconsistencies?

• Yes, abnormal slump results can indicate variations in water content, aggregate grading, or batching errors. - Is concrete slump testing required on construction sites?

• It is widely used as a standard quality control procedure to monitor fresh concrete before placement.